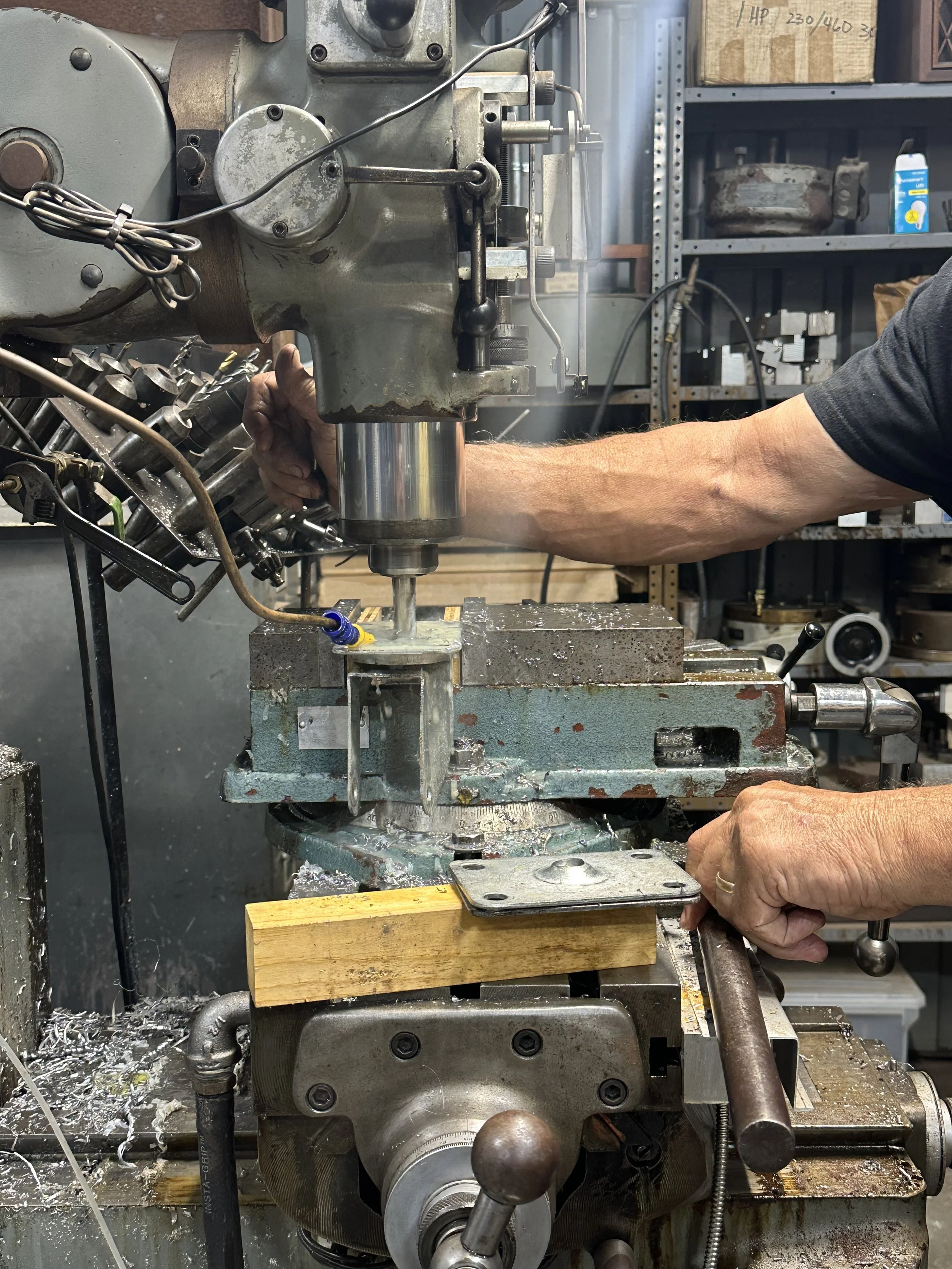

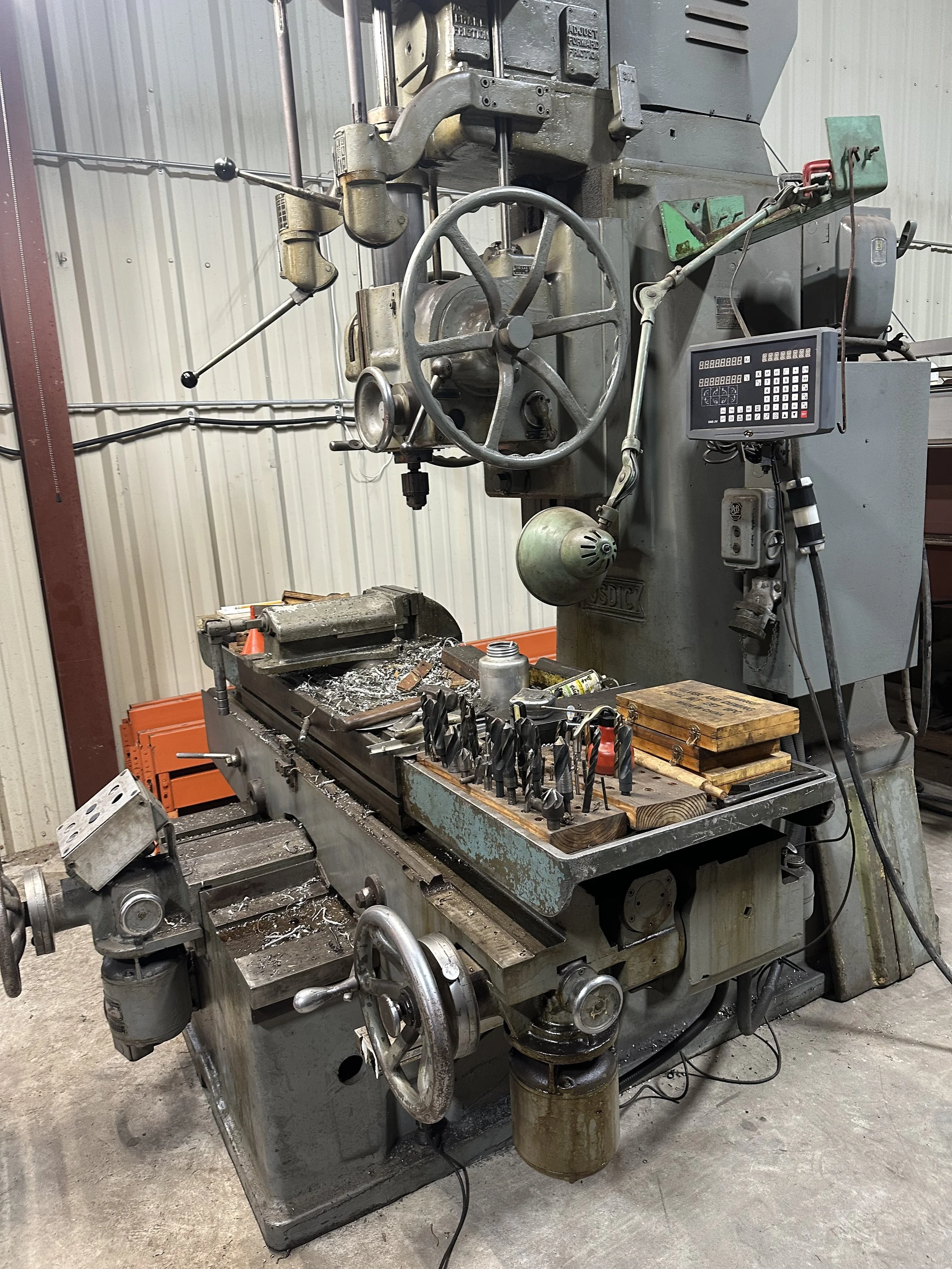

Fosdick Jig Borer – Precision Machining for Tight Applications

Our Fosdick Jig Borer may be a legacy machine, but it continues to deliver the kind of accuracy that modern projects demand. Old doesn’t mean outdated—this tool was built for precision, and we rely on it for detailed boring, drilling, and milling work where exact positioning is critical.

It’s especially useful for producing tooling, fixture components, and precision parts that require consistent repeatability and fine tolerances.

specifications:

Large Working Surface:

22" x 44" Table

Provides ample space for larger components or multi-part setups, improving throughput and flexibility.

High-Speed Spindle:

1,500 RPM

Allows for efficient material removal while maintaining tight configurations—ideal for toolmaking, fixtures, and detailed part work.

Precision Readouts:

2-Axis Digital Readout (DRO)

Improves accuracy and repeatability by providing real-time positioning data during setup and operation.

Built for Accuracy:

Designed specifically for applications where exact hole locations and high-precision alignment are critical.